Achievement

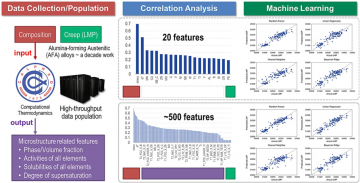

Oak Ridge National Laboratory scientists introduced a modern data analytics workflow that has potential to reduce the number of prototype samples for experimental validation by leveraging consistently measured high-quality data and relevant large synthetic datasets of selected scientific features. They used an example of the creep resistance represented as LMP of developmental AFA alloys, of which data have been collected over a decade and detailed metadata (e.g., analyzed alloy composition and processing history) is available. They have interrogated state-of-the-art computational thermodynamic databases to compute microstructure-related alloy features, such as phase/volume fraction, chemistry, and degree of supersaturation, in a high-throughput manner. They then performed extensive correlation analyses and machine learning tasks to identify key features that affect LMP of AFA alloys and confirmed that highly ranked features concur with generally accepted strengthening mechanisms. Some additional insights regarding the potential importance of individual phase chemistries not considered in the original AFA alloy design effort have been also obtained.

Significance and Impact

The demonstrated data analytics approach that combines correlation analysis and machine learning may offer significant opportunities to improve high-temperature alloy design in the near future. The approach can be expanded to accommodate additional important scientific features other than thermodynamics-based ones, such as those related to diffusion kinetics, coarsening, and microstructure morphology (e.g., precipitate size, shape, and distribution), which can have significant impact on alloy development process. The study emphasizes the role of domain experts will be critical to create a feature strategy that concurrently considers the most relevant feature set at different alloy physics and length-scales.

Research Details

- High-quality experimental creep data for training various machine learning models.

- Correlation analysis to rank features that affect alloy creep represented as Larson-Miller Parameters (LMPs).

- High-throughput CALPHAD approach to populate scientific alloy features.

- Alloy hypothesis generation to design advanced high-temperature alloys.

Overview

A breakthrough in alloy design often requires comprehensive understanding in complex multi-component/multi-phase systems to generate novel material hypotheses. We introduce a modern data analytics workflow that leverages high-quality experimental data augmented with advanced features obtained from high-fidelity models. Herein, we use an example of a consistently-measured creep dataset of developmental high-temperature alloy combined with scientific alloy features populated from a high-throughput computational thermodynamic approach. Extensive correlation analyses provide ranking insights for most impactful alloy features for creep resistance, evaluated from a large set of candidate features suggested by domain experts. We also show that we can accurately train machine learning models by integrating high-ranking features obtained from correlation analyses. The demonstrated approach can be extended beyond incorporating thermodynamic features, with input from domain experts used to compile lists of features from other alloy physics, such as diffusion kinetics and micro-structure evolution.

Last Updated: January 15, 2021 - 12:38 pm